Why Copper Products Are Necessary for Electrical Applications and Efficient Electrical Wiring

Why Copper Products Are Necessary for Electrical Applications and Efficient Electrical Wiring

Blog Article

The Value of Quality in the Manufacturing of Copper Products

The relevance of high quality in the manufacturing of copper items prolongs much past simple compliance; it is integral to maximizing performance across various markets. High-grade copper not only enhances conductivity however likewise guarantees resilience and dependability, which are essential in applications varying from electronics to vehicle systems. The ramifications of bad manufacturing techniques can resound via prices and security standards, eventually influencing customer trust. As we check out the complex nature of top quality, the inquiry occurs: how can producers balance these obstacles to accomplish excellence?

Influence On Product Performance

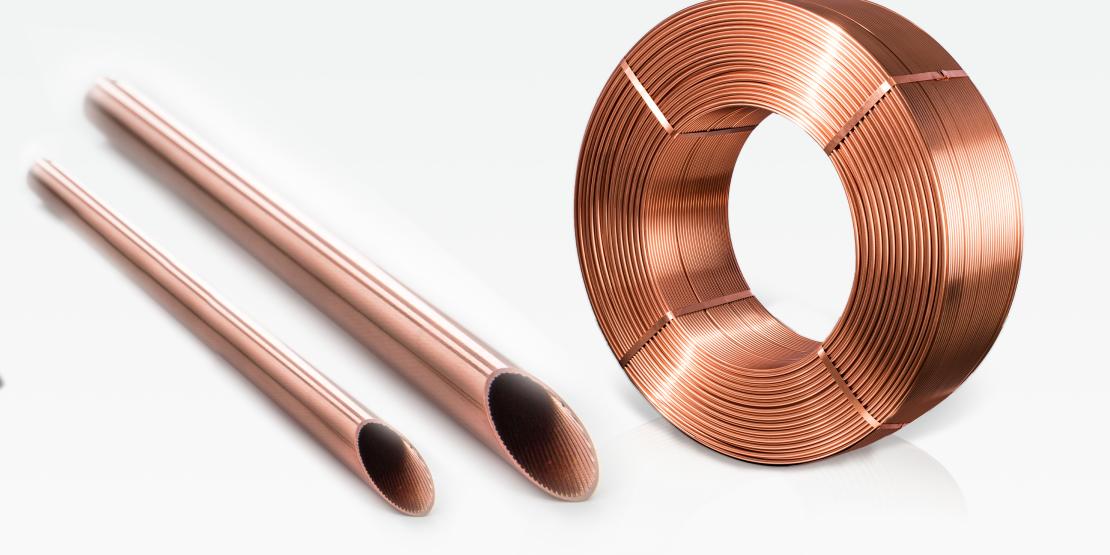

The high quality of copper products plays an essential function in identifying their general performance in numerous applications. High-quality copper shows superior electric conductivity, thermal conductivity, and rust resistance, which are important qualities for sectors such as electronics, building and construction, and automotive. In electric applications, for example, high-purity copper decreases power loss during transmission, making certain reliable power shipment. This efficiency is important for the long life and integrity of electric systems.

In addition, the mechanical homes of copper, consisting of ductility and tensile toughness, substantially influence its performance in making processes. Copper items that fulfill rigorous top quality requirements can endure considerable stress and anxiety without flawing, therefore boosting resilience and decreasing the chance of failing in requiring settings.

Additionally, the surface coating of copper products effects their performance. A smooth, well-treated surface area can stop oxidation and various other types of degradation, inevitably extending the life of the element. In summary, the top quality of copper items directly influences their performance, integrity, and long life throughout numerous markets, making it important for suppliers to follow rigorous high quality control measures throughout the production process.

Price Ramifications mediocre

Investing in high-quality copper items is vital, as the expense effects of poor high quality can be considerable for producers and end-users alike. Poor quality copper can lead to enhanced failing prices, causing pricey repairs and substitutes. Producers may encounter substantial downtime as faulty items necessitate remembers or rework, disrupting production timetables and influencing overall efficiency.

From an end-user point of view, the implications are equally severe. Poor-quality copper can lead to inadequacies and boosted operational expenses, as equipment may require even more regular maintenance. Inevitably, the first cost savings gotten from choosing lower-quality copper products can be eclipsed by these long-term costs, making the quest of high quality not just an issue of performance, but an essential financial factor to consider in the production industry.

Security and Compliance Criteria

Making sure safety and security and compliance requirements in the manufacturing of copper items is essential to keeping functional honesty and safeguarding both staff members and customers. The manufacturing process have to stick to rigid regulations established forth by organizations such as the Occupational Security and Health Management (OSHA) and the Epa (EPA) These policies outline crucial safety and security techniques, consisting of proper handling of basic materials and waste administration, guaranteeing a risk-free workplace.

In addition, compliance with sector requirements such as ASTM International and ISO qualification is essential. These companies supply standards that aid makers execute finest methods in quality control and precaution. Regular audits and examinations ought to be performed to make certain adherence to these requirements, as non-compliance can cause harmful problems and possible lawful ramifications.

Customer Trust Fund and Contentment

Trust fund and contentment among customers play a critical duty in the success of copper item producers (Copper Products). Top quality copper products not just fulfill rigorous sector standards yet likewise fulfill client expectations, cultivating loyalty and repeat business. When clients are positive in the high quality of the items they buy, they are more probable to establish a long-lasting partnership with the manufacturer, which can lead to recommendations and favorable word-of-mouth

To construct this trust, suppliers must focus on high quality control throughout the manufacturing process, making sure that each copper thing satisfies or exceeds requirements. Openness in manufacturing practices, coupled with dedication to client service, enhances the assumption of integrity. Timely distribution and responsiveness to consumer questions substantially boost complete satisfaction degrees.

Client responses ought to be actively sought and incorporated right into item development cycles to continually boost offerings. Engaging clients in dialogue about their preferences and needs grows a sense of collaboration, more strengthening their count on the maker. Eventually, a reputation for high quality and customer-centric practices distinguishes effective copper product suppliers in a competitive market, laying the groundwork for withstanding customer connections.

Lasting Company Success

A producer's commitment to high quality is indispensable to achieving long-lasting business success in the competitive copper products market. High-grade items foster client loyalty, making sure repeat company and favorable references that drive development. In an industry where reliability and performance are critical, business that prioritize top quality over cost-cutting go to the website procedures are more probable to stand out.

Moreover, consistent high quality reduces the incident of defects and revamp, bring about lower functional prices and raised efficiency. This streamlined production process enables manufacturers to designate resources successfully, enabling investments in advancement and innovation. Companies that adapt to spend and market changes in quality improvements are better placed to satisfy evolving client needs.

Furthermore, maintaining stringent high quality criteria improves a click for more info business's reputation, attracting possible partnerships and new customers. A durable credibility for high quality can offer as a differentiator in crowded markets, opening up doors to lucrative contracts and collaborations.

Inevitably, a steadfast dedication to quality not just makes certain compliance with industry regulations but likewise cultivates a lasting service design. By installing high quality into every facet of the manufacturing process, companies can safeguard their place as leaders in the copper items industry, leading the way for enduring success.

Conclusion

In verdict, the importance of high quality in copper product production is extremely important. Top quality products improve performance, minimize prices connected with failings, and guarantee conformity with security standards. In addition, focusing on quality cultivates consumer depend on and complete satisfaction, which are vital for maintaining lasting business success. As markets significantly rely upon copper for crucial applications, preserving rigorous top quality control is crucial to safeguard a competitive benefit and promote a trusted market existence.

The value of top quality in the manufacturing of copper products extends far beyond mere conformity; it is important to enhancing performance throughout various markets. In summary, the top quality of copper products directly see page impacts their performance, integrity, and long life throughout numerous sectors, making it essential for producers to stick to rigorous high quality control steps throughout the production process.

A producer's commitment to high quality is important to achieving long-term company success in the affordable copper products market.

Report this page